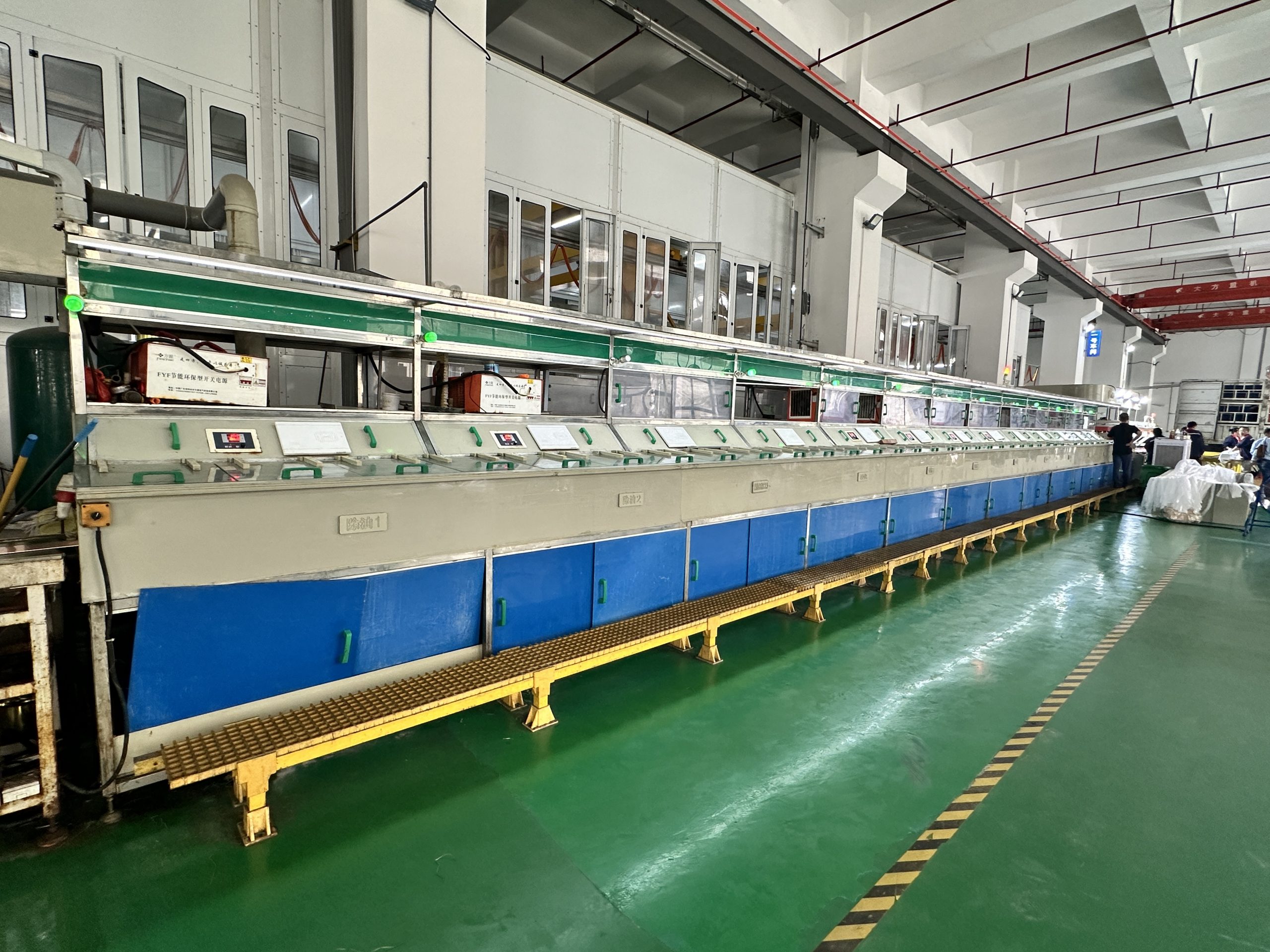

Description of main components

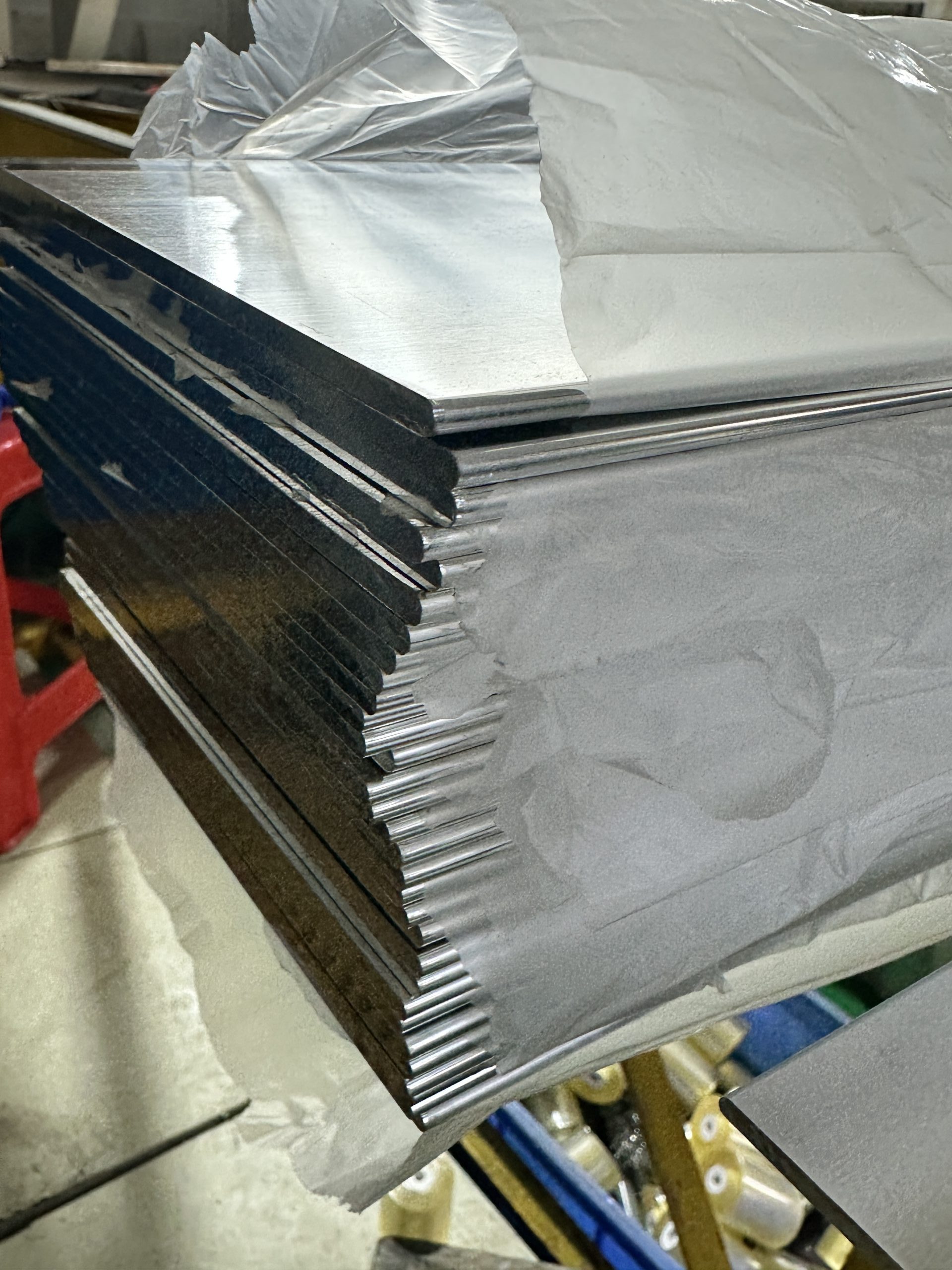

1 Busbar auto feeding rack:

Put the bright busbar horizontally on the feeding rack; the rack can automatically turn over the busbar to vertical status and send it to the cleaning channel by feeding rollers.

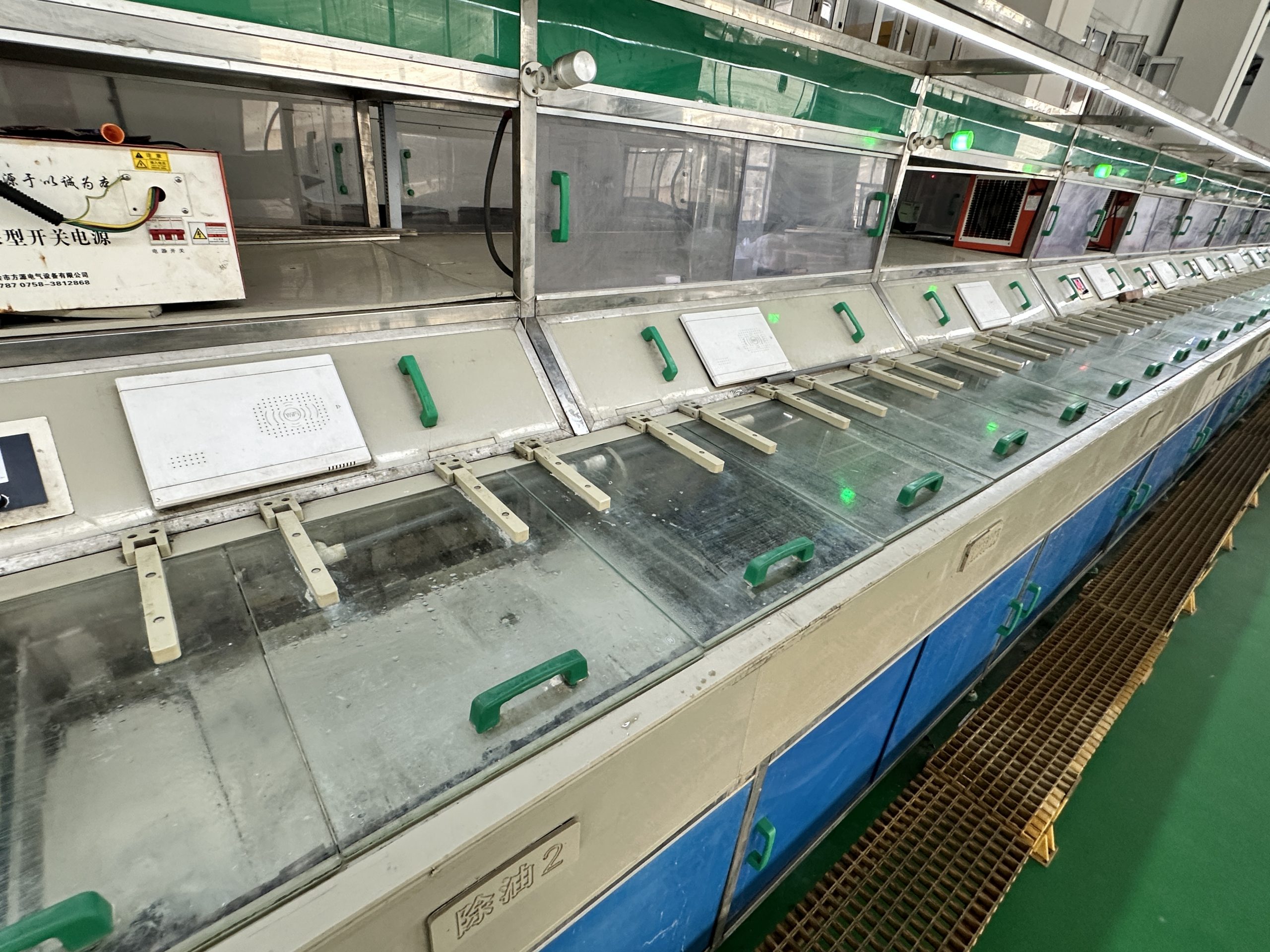

2 Conductive flush cleaning section:

After receiving the signal, the hauling device will clamp the busbar and the conductive wheels will contact the busbar. During this section, the busbar will go through the electrolytic degreasing and oil-removing process.

3 Antioxidation cleaning section:

The antioxidation cleaning process is the last cleaning paragraph before the tin plating.

4 Tin plating section:

The tin plating section is divided into three parts, which can ensure the busbar gets the uniform plating effect and plating thickness.

5 Cleaning after plating:

This process is to clean the residual acid at the busbar’s surface

6 Warm water cleaning section:

This process is for the further cleaning

7 Hot wind drying section:

In order to clean the residual water on the busbar surface after cleaning, hot wind drying is adopted to remove the water.

8 Take up and overturn rack:

After the tin plating, the vertical busbars pass the conveying roller rail, then turn to the horizontal status and slip into the stacking device through rubber wheels. In order to avoid the scratch, the slipping distance can be adjusted.

9 Electric control system:

The system consists of 1 main control cabinet and 2 consoles. The control system is divided into plating parts and mechanical parts.

Each section of the plating part is equipped with a hauling device, which receives the signal through the photoelectric sensor and carries out the hauling action.

The worker can set the voltage and current in the control cabinet.

10 Waste gas collecting and cleaning tower:

After the heating, the acid in the tin plating tanks will generate a small amount of acid mist. In order to reduce air pollution, the waste gas will be collected and sent to a cleaning tower for purification.

11 Waste water purify treatment device:

There is a small amount of waste water in the cleaning cycle of tin plating production. The waste water can be neutralized and filtered by purifying device to reach the standard of reuse water.

Product Category

Product Category More

More

More

More