Composed transport conductor:

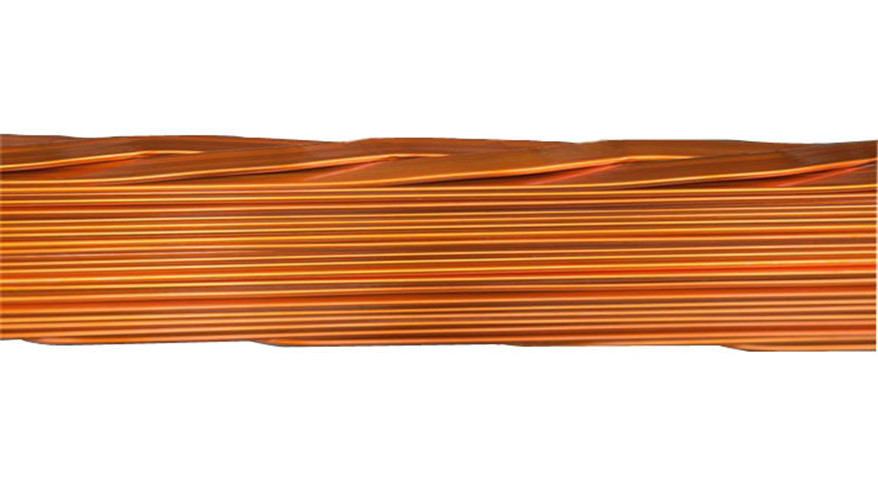

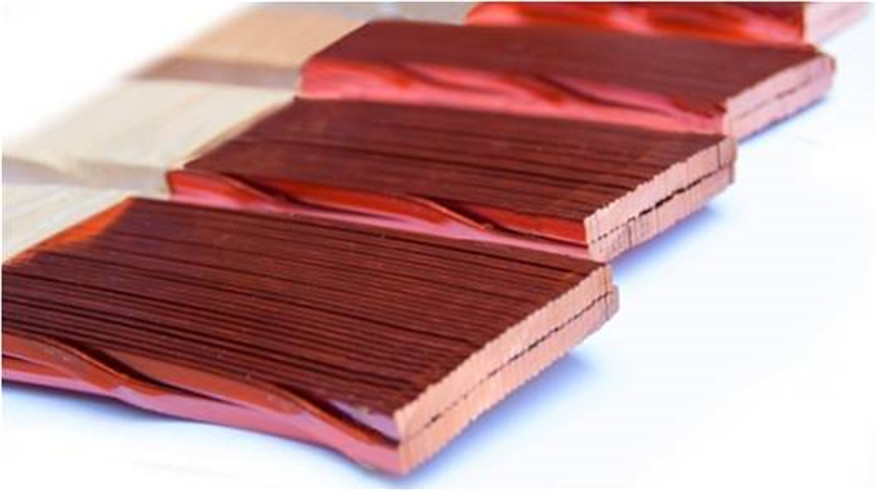

Transposed conductor refers to the combination of a certain number of enameled copper flat wires into two rows with wide surfaces that are in contact with each other, and the upper row and lower row enameled wires are transposed in the same direction along the narrow surface, and electrical insulation paper is continuously tightly wrapped into multilayer.

The windings of large power transformers adopt transposed wires, which can greatly reduce load loss, reduce the temperature rise of winding hot spots, improve the mechanical strength of the windings, make the structure more compact, and the coil processing is easier, so the transposed wires have been used in large power transformers once they came out. It has been widely used in winding design and manufacturing.

Production range:

Flat wire thickness 1.1-3.15mm; width 3-12.5mm

Wire quantity from 8 to 96pcs

Transposed conductor max height 75mm; max.width 26mm

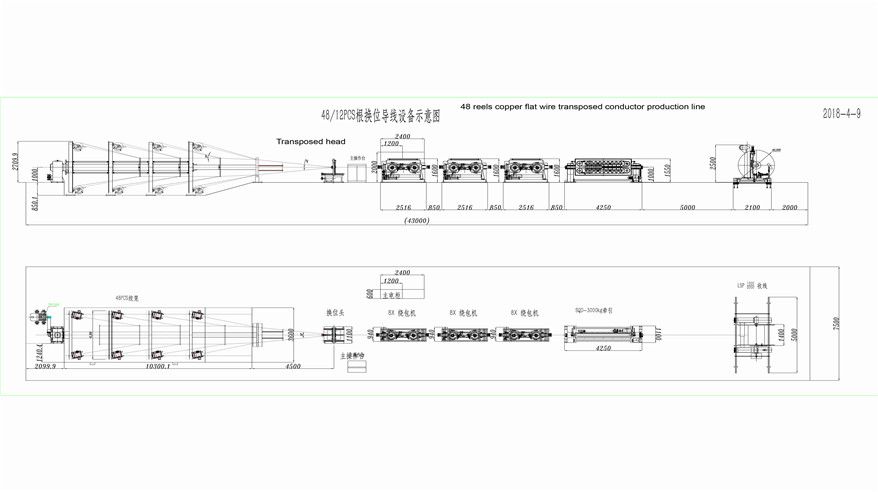

CTC line production process (48 strips)

The CTC machine is composed of Wring Cage (Force level control), Taping head for wrapping 8 layers, 90 degree tumbler type pneumatic caterpillar traction, Portal railway moving type take up, Touch screen display and Electric numerical control.

The technical specification for single strip:

Soft state or semi-hard copper flat wire, thickness a: 1.0~3.15mm, width b: 3.0~12.5mm;

Speed of wring cage:1~15r/min;

Traction speed:0~20m/min;

The center of the production line:1000mm

Product Category

Product Category More

More

More

More

More

More