Anode electrolysis also called two-step electrolysis. It is more suitable for bigger capacity production with raw material that has lower copper scrap rate (<95%copper purity). The process first transmits copper scrap to anode plates, then do the electrolysis for copper cathode production.

Anode plate process flow:

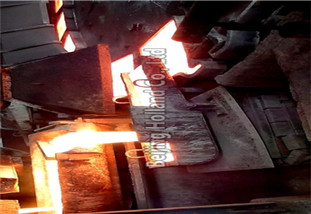

Charging copper scrap-> melting-> oxidation-> reductance-> disc casting-> assorting&trimming-> anode plate

Main machinery: Quantitative disc casting machine

Features:

Quantitative disc casting machine is a large-scale smelting and production equipment that can be used to cast the molten copper (also can be used for lead, tin and other non-ferrous metals) in the state of smelting into the anode plate with a specific shape, specification and weight requirements through an automatic process. The equipment has two functions: full automation of the production process and optional setting of anode weight.

Advantages:

· Full automation

· Patent weight control system of the anode plate

· Time-division control technology and fuzzy control technology to ensure the precision of quantitative casting.

· Disc body adopts time-division control technology and closed-loop control technology, center support, center drive or outer gear ring drive optional, disc drive accurate, stable speed, avoid flanging, to ensure the physical specification of the anode.

· The number of positive plates can be set, convenient forklift scheduling.

· The hydraulic station has a power protection function, so that the tundish, casting bag in the sudden power after the reset.

Product Category

Product Category More

More

More

More

More

More

More

More