Molten Aluminum Ladle Preheater

Brief introduction:

The transfer ladle preheating equipment, also known as ladle heater, is mainly used to quickly and uniformly increase the temperature of the molten aluminum ladle lining to reduce heat loss during molten aluminum pouring and prolong the service life of the molten aluminum ladle lining. including gas type and electric type.

Gas heating transfer ladle preheater:

• Natural gas (NG) or LPG is chosen as the fuel.

• The baking rate is adjustable within a wide range.

• Fully combusted, energy-saving and environment-friendly.

• Suitable for molten aluminum ladles of different heights.

• Equipped with a conventional high-speed gas burner and a self-preheating burner.

• Gas and combustion air pressure detection, abnormal ignition alarm.

• Controllable baking temperature and time.

• Open flame ignition function.

• Flame detection function.

Electric heating transfer ladle preheater:

• Uniform baking temperature.

• Low heat emission.

• A high-efficiency squirrel-cage heater is used.

• A baking curve can be set freely.

• Controllable baking temperature and time.

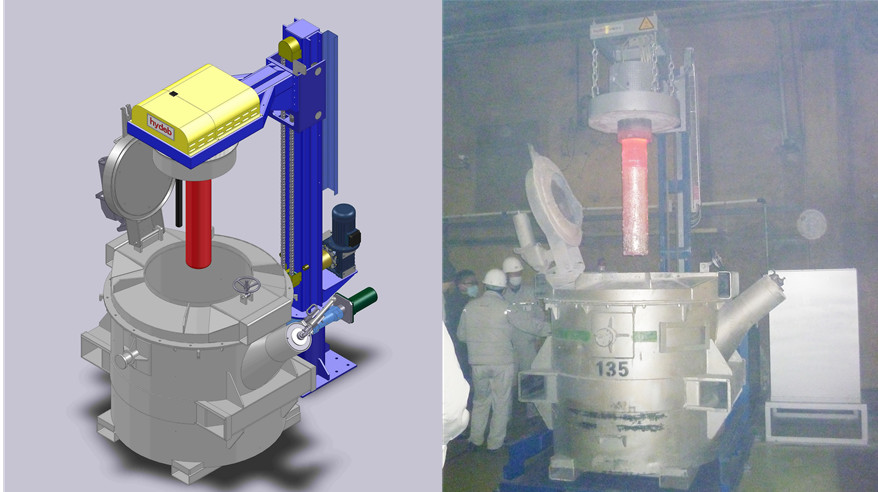

Immersion molten aluminum heating equipment

Brief Introduction:

The immersion molten aluminum heating equipment is mainly used for heating and heat preservation of the molten aluminum in the ladle. The ceramic heater is directly immersed in molten aluminum to heat the molten aluminum from the inside. The molten aluminum can be kept high-quality for a long period of time owing to the high thermal efficiency and low molten aluminum oxidation.

Equipment Features

• Electric or gas heating, under automatic temperature control.

• High heating rate and thermal efficiency. The immersion heater transfers heat directly in molten aluminum, ensuring high thermal efficiency and heating rate.

• High-temperature uniformity of molten aluminum. Immersion heat is directly transmitted to the molten aluminum in the ladle, so there is little difference in molten aluminum temperature in the whole ladle.

• Few oxide inclusions in molten aluminum. Radiation heating accelerates the oxidation of molten aluminum surface, resulting in a large amount of oxide slags; however, immersion heating keeps molten aluminum surface micro-thermal, thus greatly reducing oxidizing slags on the molten aluminum surface.

• The molten aluminum rarely tends to absorb air. Air absorption in molten aluminum is directly proportional to molten aluminum surface temperature. Immersion heating makes the molten aluminum surface temperature consistent with the internal temperature, thus greatly reducing air absorption in molten aluminum.

Technical Parameters

• Heating rate: ≥25℃/h

• Heating power: ≥20kw/1000kg (AL)

• Molten aluminum temperature uniformity: ≤±5°C

• Service life of heater protection tube: ≥6 months

Product Category

Product Category More

More