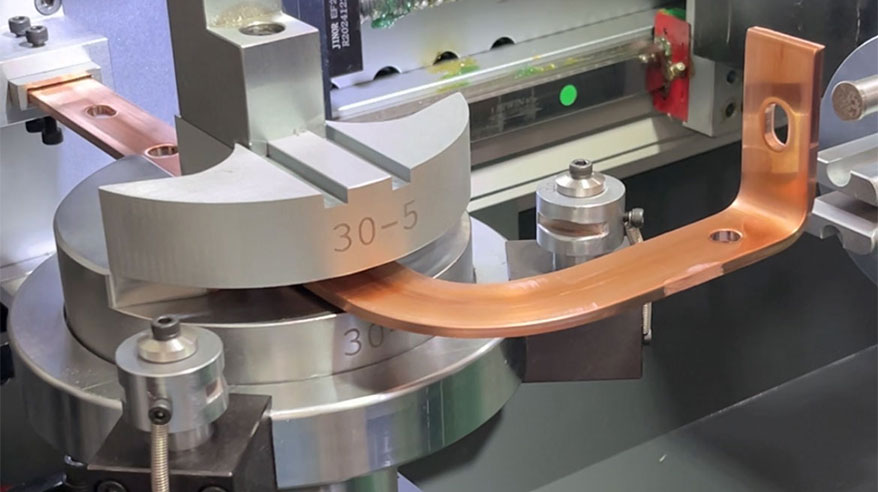

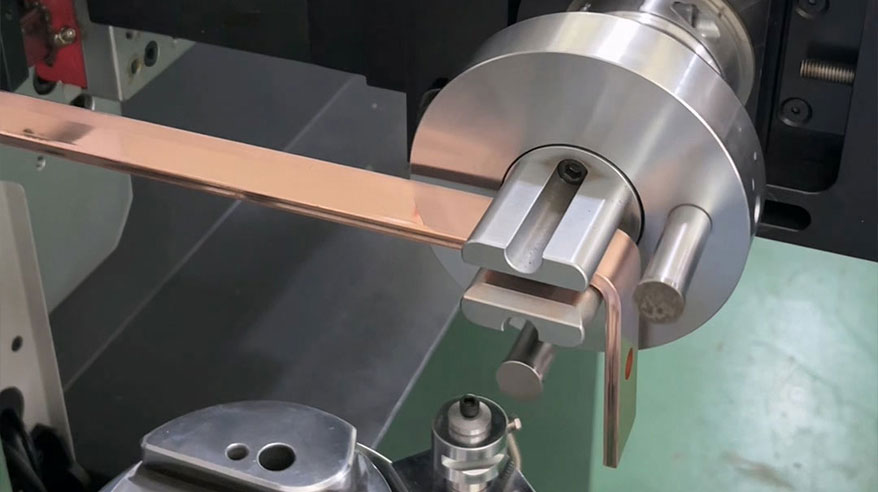

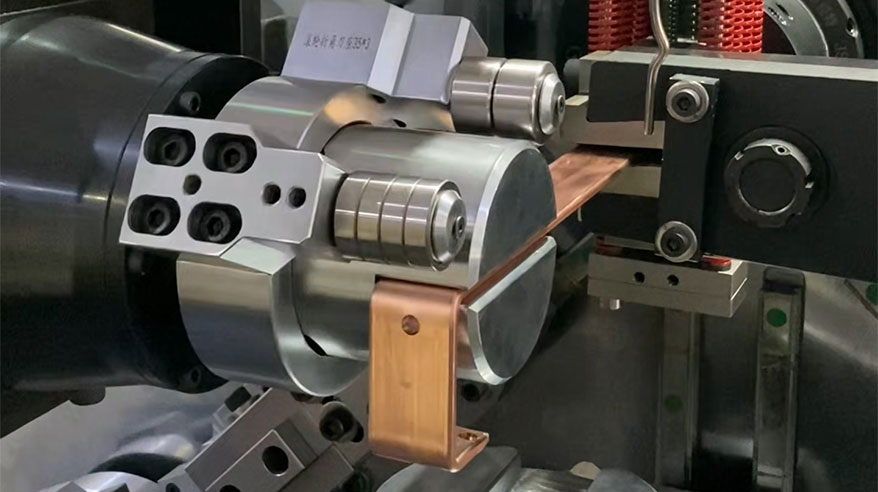

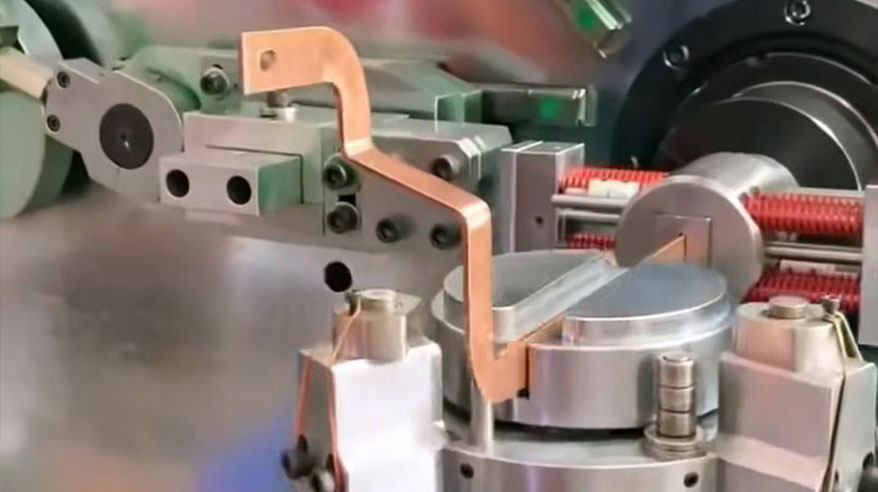

Busbar processing machines are among the most utilized devices in the industry. We provide our customers

with a full range of busbar processing machine capable of bending busbars into various shapes for

installation in electrical panels and switchgears for diverse applications. Our scope includes:

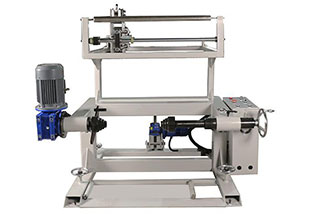

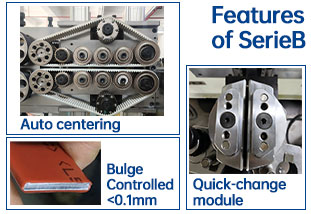

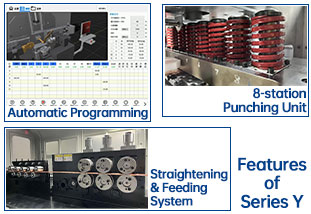

• Fully-automatic CNC processing machine – Y & B Series

• Semi-Auto (Optional CNC bending) processing machine – LJ Series

Product Category

Product Category